51

Methods

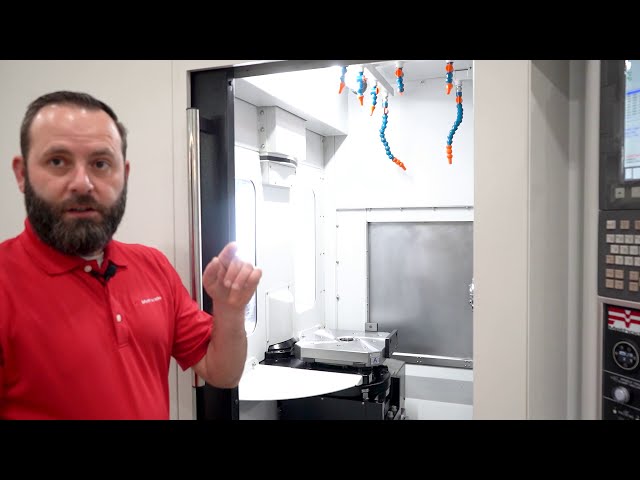

MH 320A

The MH 320A Series offers an integrated full rotary B-Axis and a reliable FANUC 0i-MF control with a 15 in. LCD screen. The machine features excellent chip evacuation and easy access for set-up/maintenance. A spindle oil cooling system and coolant-through ball-screws are standard.

The MH 320A has a compact footprint of 140 in. depth x 107 in. width including the chip conveyor.

Product Details

Features & Benefits

- Dual 320mm Pallets

- Roller Guide Ways

- 20HP/15,000rpm Direct Drive

- Dual Contact Spindle 40 Taper

- 15” Fanuc LCD Screen

- Coolant Through Ballscrews (CTB)

- Integrated Full Rotary B-Axis

- Excellent Chip Evacuation

- Easy Access for Setup & Maintenance

Technical Data

Travel

- X-Axis Travel

- 18.1 (460) in (mm)

- Y-Axis Travel

- 18.1 (460) in (mm)

- Z-Axis Travel

- 13.7 (350) in (mm)

- 4th Axis Travel (Rotary Table)

- 0-360 degrees

Pallet

- Pallet Surface to Spindle Center

- 2.36-20.4 (60-520) in (mm)

- Pallet Center to Spindle Nose

- 2.36-16.1 (60-409) in (mm)

- Pallet Size

- 12.9x12.9 (320x320) in (mm)

- Pallet Load Capacity

- 550 (250) lbs (kg)

- Max. Workpiece Size

- 16.9x18.7 (430x475) in (mm)

- Pallet change Time

- 8 sec

Feed Rate

- X-Axis Rapid Traverse

- 1968 (50) in/min (m/min)

- Y-Axis Rapid Traverse

- 1968 (50) in/min (m/min)

- Z-Axis Rapid Traverse

- 1968 (50) in/min (m/min)

- 4th Axis

- 41 rpm

- Cutting Feed (X/Y/Z)

- 787 (20) in/min (m/min)

Spindle

- Spindle Power

- 20 HP

- Spindle Speed

- 15000 rpm

- Spindle Taper

- Cat 40 Taper

Tools

- Standard Number of Tools

- 40 std

- Maximum Tool Weight

- 17.6 (8) lbs (kg)

- Maximum Tool Length

- 12.6 (320) in (mm)

- Maximum Tool Diameter

- ø 3.14 (80) in (mm)

- Maximum Tool Diameter- No Adjacent Tool

- 6.29 (160) in (mm)

- Tool Changing Time- Tool to Tool

- 2.5 sec

General

- Coolant Tank Capacity

- 80 (303) gal (L)

- Machine Weight

- 13889 (6300) lbs (kg)

- Machine Control

- FANUC 0i-MF