51

OKK

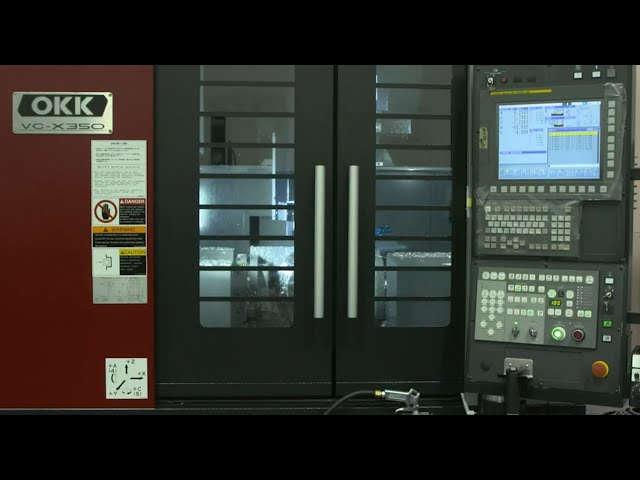

VC-X350

*Availability of machines is based on region. Contact your local Methods office to learn more.

The VC-X350 is a specialized 5-axis machining center developed from OKK’s advanced technologies. This machine eliminates loss of accuracy and burden on the operators caused by multi-setup operations, and also shortens lead times through process integration.

Ideal for integration with an Automatic Work Changer, the VC-X350 includes a magazine with 60 capacity, is extremely rigid, and features a table that can handle titanium and other hard metals.

Product Details

Features & Benefits

- Environment-friendly space saving design for economical use of floor space

- Powerfully Smooth Feed

- Core chilled ball screw and Double-anchor pre-tension system

- Two coil-type chip conveyors

Technical Data

Travel

- X-Axis Travel

- 23.6" (600mm)

- Y-Axis Travel

- 16.9" (430mm)

- Z-Axis Travel

- 18.1" (460mm)

- A-Axis Travel

- ‐120° to +30°

- C-Axis Travel

- 360°

- Table Top to Spindle Nose

- 2.8 - 20.87" (70mm - 530mm)

Table

- Table Work Surface Area

- Ø 13.8" (350mm)

- Table Load Capacity

- 440 lbs (200 kg)

Feed Rate

- Rapid Traverse Rate X/Y

- 1969 in/min (50 m/min)

- Rapid Traverse Rate Z

- 1417 in/min (36 m/min)

- Cutting Feed (X/Y/Z)

- 1417 in/min (36 m/min)

Spindle

- Spindle Power

- 50/30 HP

- Spindle Speed

- 12,000 rpm

- Spindle Taper

- CAT40

Tools

- Standard Number of Tools

- 60 (OP: 80/120)

- Maximum Tool Weight

- 15.4 lbs (7 kg)

- Maximum Tool Length

- 11.8" (300 mm)

- Maximum Tool Diameter

- ø 3.2" (82 mm) / ø 4.9" (125 mm) without adjacent tool

- Tool Changing Time- Tool to Tool

- 1.3 sec

General

- Machine Weight

- 18,700 lbs (8,500 kg)

- Machine Control

- FANUC F31i-B5